Mining for the Future: What Sustainability Actually Looks Like at Scully Mine

Mining for the Future: What Sustainability Actually Looks Like at Scully Mine

There’s a lot of talk about sustainability in mining. For some, it’s still just talk. But at Tacora’s Scully Mine in Wabush, Labrador, sustainability is baked into the way we operate, not as a marketing angle, but as a commitment to doing things differently, and doing them better.

We know mining has a footprint. We also know that the demand for iron ore, especially the high-grade, low-impurity kind we produce, is only growing as the world shifts to low-carbon infrastructure. So we’re not pretending this work comes without impact. But we are proving that it can be done with care, intention, and real results.

Restoring What We Disturb: Not Later, but Now

At many mine sites, land restoration is something you think about at the end. For us, it starts on Day One.

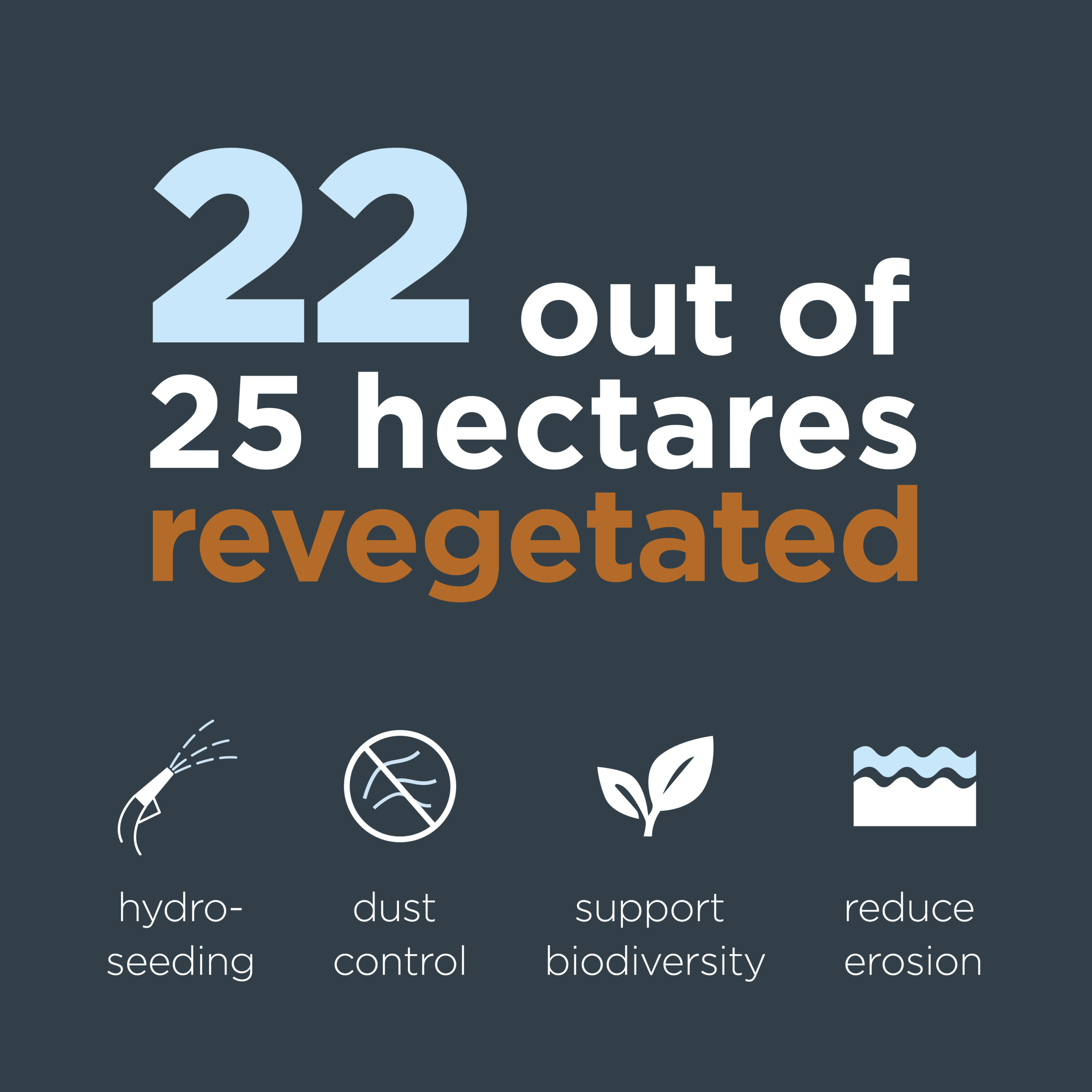

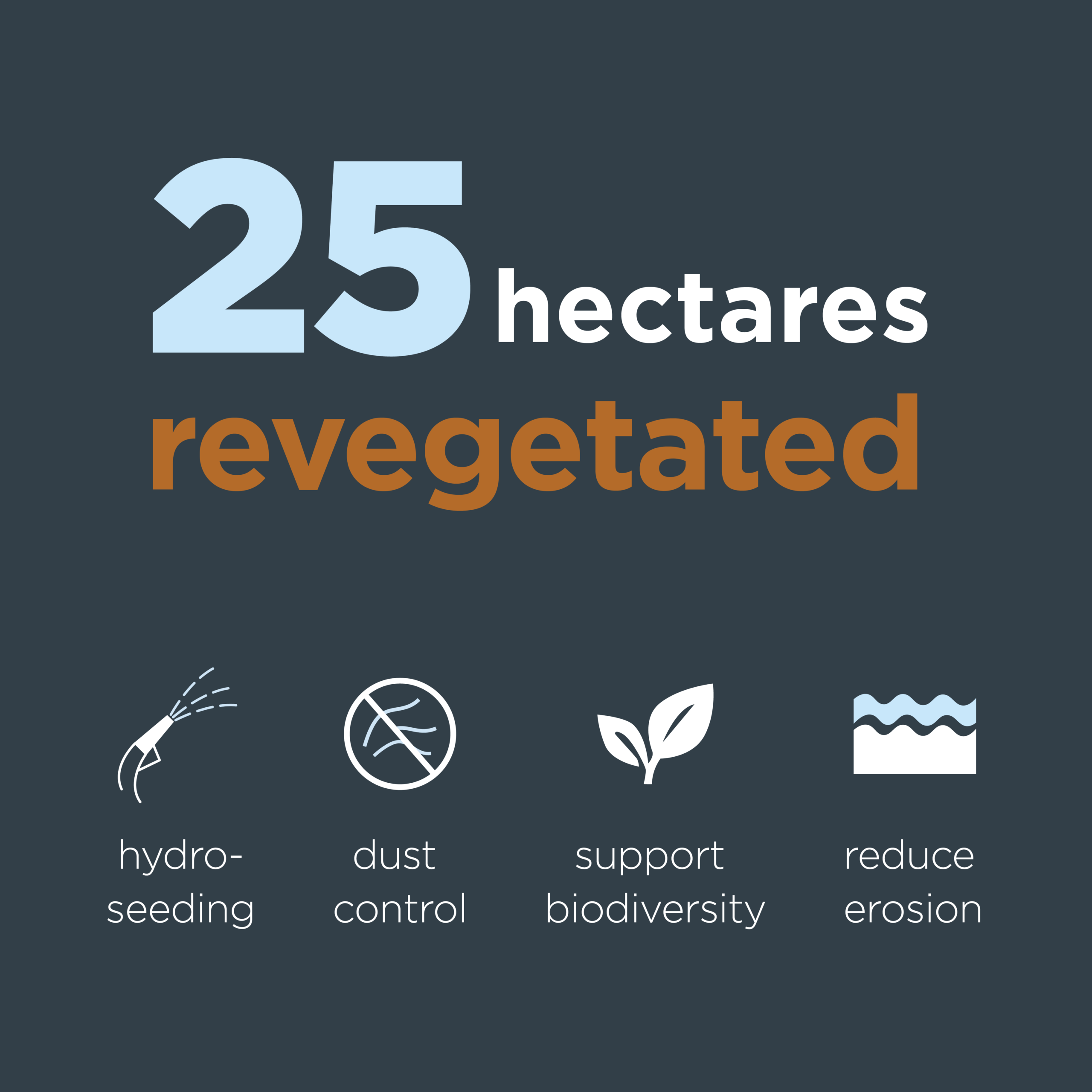

In 2023, we revegetated 22 of 25 hectares of disturbed land using hydroseeding and native plants, helping control dust, reduce erosion, and support biodiversity returning to the site. That kind of progressive rehabilitation is rare, and we think it shouldn’t be.

Restoring What We Disturb: Not Later, but Now

At many mine sites, land restoration is something you think about at the end. For us, it starts on Day One. In 2023, we revegetated 25 hectares of disturbed land. Of those, 22 hectares were restored using hydroseeding and native plants, helping to control dust, reduce erosion, and support the return of biodiversity to the site. Progressive rehabilitation like this is rare, but we believe it shouldn’t be.Rewriting the Water Story

Mining operations around the world are facing water shortages, especially in places where demand is rising and droughts are intensifying. While we’re fortunate in Labrador, we’re not taking that for granted.Rewriting the Water Story

Mining operations around the world are facing water shortages, especially in places where demand is rising and droughts are intensifying. While we’re fortunate in Labrador, we’re not taking that for granted.

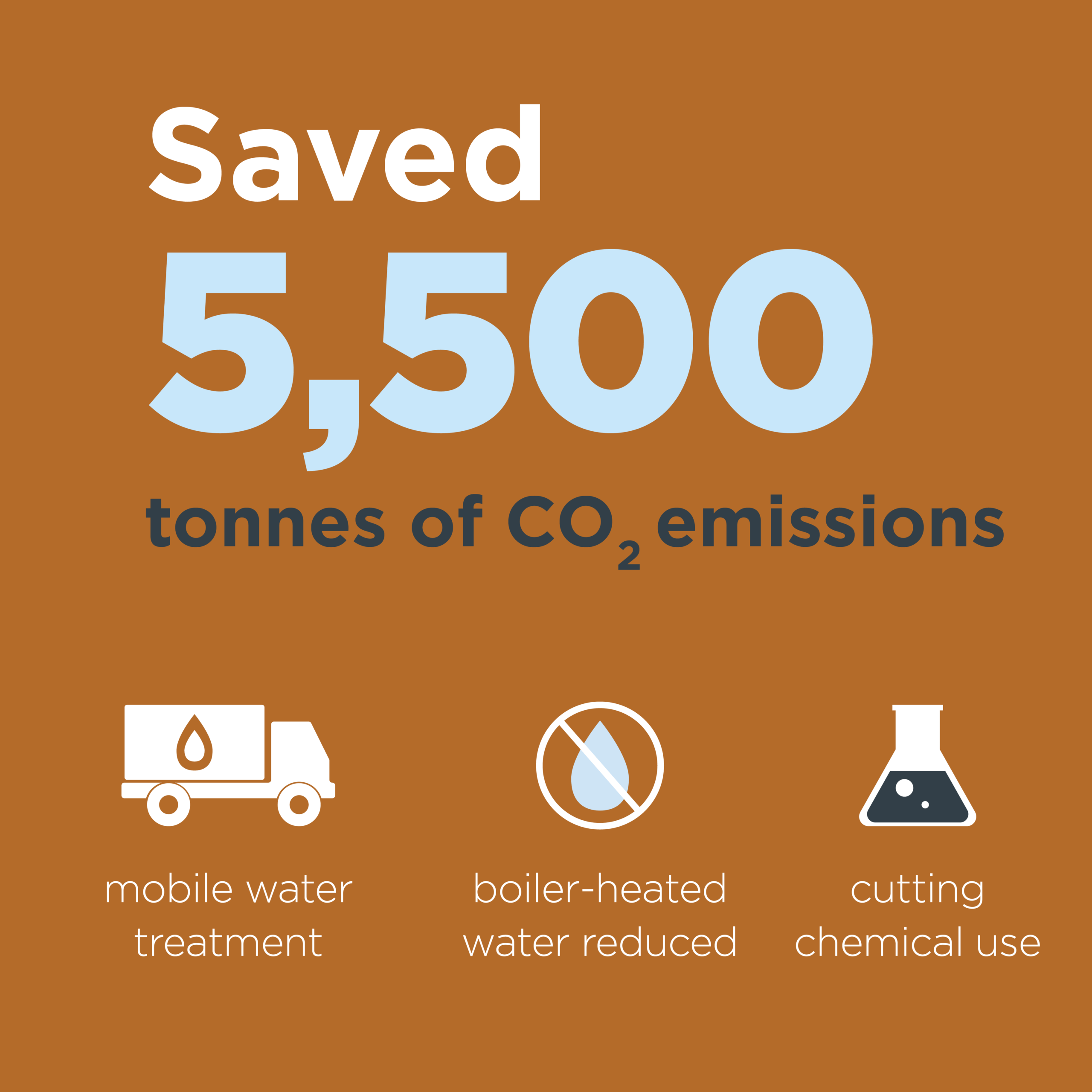

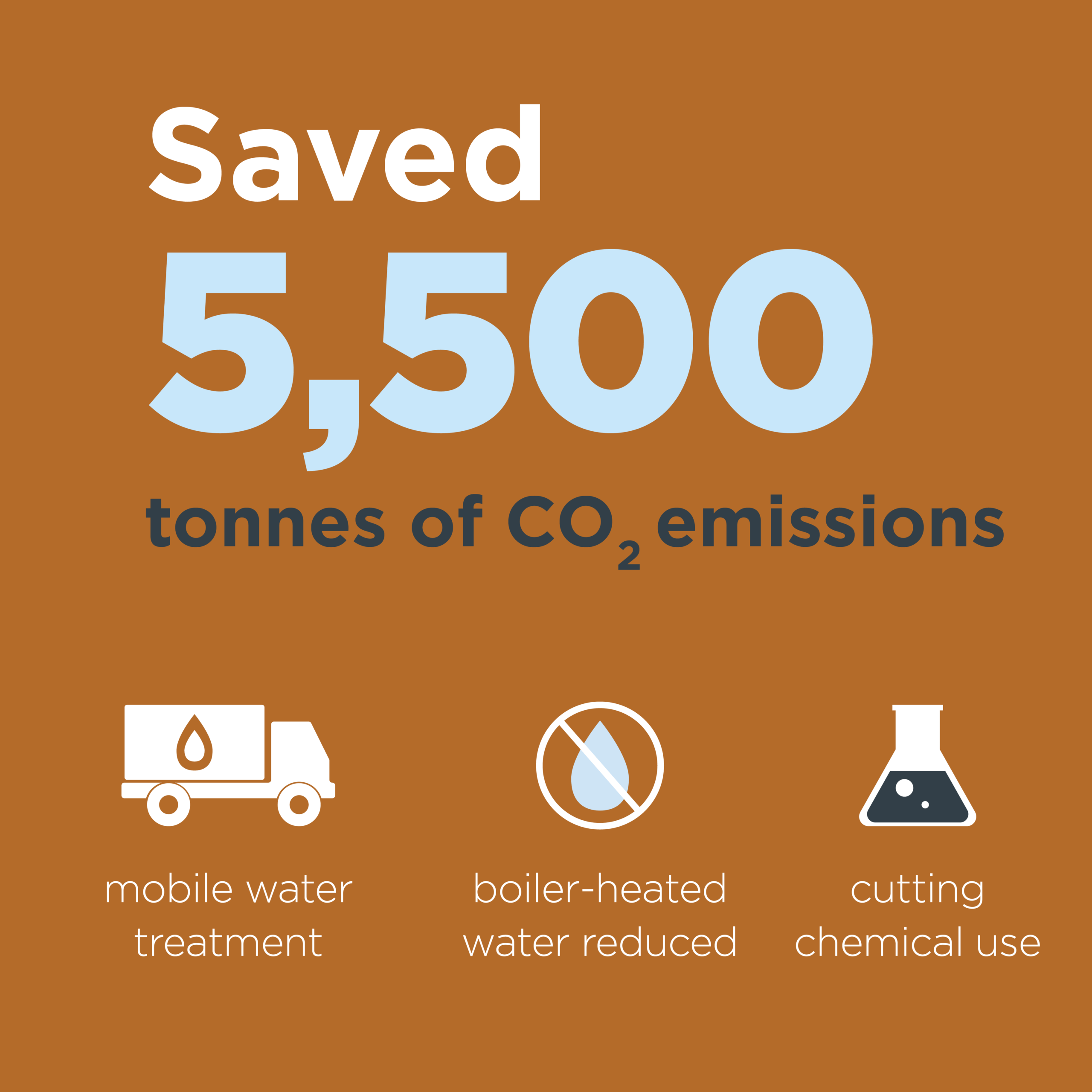

We’ve partnered with Veolia to deploy mobile water treatment systems at site, reducing our need for boiler-heated water, cutting chemical use, and saving over 5,500 tonnes of CO₂ emissions in just two months. That change also saved us over $1.3 million in operating costs. It’s a rare win-win — better for the environment and the bottom line.

We’ve partnered with Veolia to deploy mobile water treatment systems at site, reducing our need for boiler-heated water, cutting chemical use, and saving over 5,500 tonnes of CO₂ emissions in just two months. That change also saved us over $1.3 million in operating costs. It’s a rare win-win — better for the environment and the bottom line.

Tailings: It’s About Doing the Harder, Smarter Thing

Let’s be honest: tailings management is one of the biggest environmental challenges in mining. And it’s often where companies cut corners.

We’re not doing that. Our preferred solution for expanded tailings storage, identified through an in-depth study with Hatch Engineering, is a compacted filtered tailings design that dramatically reduces risk of failure and limits environmental impact. It’s not the cheapest solution, but it’s the right one.